You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The 3d printing thread

- Thread starter peps1

- Start date

ax

Mod Maker

- Joined

- Feb 3, 2015

- Messages

- 654

Yes, Shapeways prices are ridicules, not sure how it work, but assume you pare paying for the part + a commission for who designed the part?

No idea, I uploaded the sled file directly, so it's not that.. just damn expensive.

peps1

Postman

- Joined

- Dec 15, 2014

- Messages

- 779

No idea, I uploaded the sled file directly, so it's not that.. just damn expensive.

You holding on on me with some sled design!!

ax

Mod Maker

- Joined

- Feb 3, 2015

- Messages

- 654

You holding on on me with some sled design!!

Nout that's not freely available on the internet..

ax

Mod Maker

- Joined

- Feb 3, 2015

- Messages

- 654

http://www.axmod.co.uk/sledfiles.zip main 2.. have a play..

Jasen

Postman

- Joined

- May 31, 2014

- Messages

- 129

SW is the cheaper option, Skulpteo is even higher. Could go to a loan shark for the money to buy a printer, but at least SW doesn't break your legs.

3D printing services in your neighborhood | makexyz.com is another option, this might be ok for some personal work, but we can't afford to invest in batches. I'd imgaine there would be a similar organisation on that side of the pond.

3D printing services in your neighborhood | makexyz.com is another option, this might be ok for some personal work, but we can't afford to invest in batches. I'd imgaine there would be a similar organisation on that side of the pond.

ax

Mod Maker

- Joined

- Feb 3, 2015

- Messages

- 654

SW is the cheaper option, Skulpteo is even higher. Could go to a loan shark for the money to buy a printer, but at least SW doesn't break your legs.

3D printing services in your neighborhood | makexyz.com is another option, this might be ok for some personal work, but we can't afford to invest in batches. I'd imgaine there would be a similar organisation on that side of the pond.

Seems you've missed the fact that peps1 has just bought a 3D printer

peps1

Postman

- Joined

- Dec 15, 2014

- Messages

- 779

Seems you've missed the fact that peps1 has just bought a 3D printer

Yep, I'm here if anyone need me to print them something! *contributing members, not just anyone who stumble across this page and decided they need a quad copter frame printed!

No charge, (well maybe shipping) just a waiting list, and the right to say "sorry to busy with other peoples prints bug me next week"!

Also been hitting the Autodesk tutorials quite hard, to get my 3D modelling skills a little better for that inevitable moment someone PMs me with "I need this part, but can you change X to Z and A to B and put this text on it"

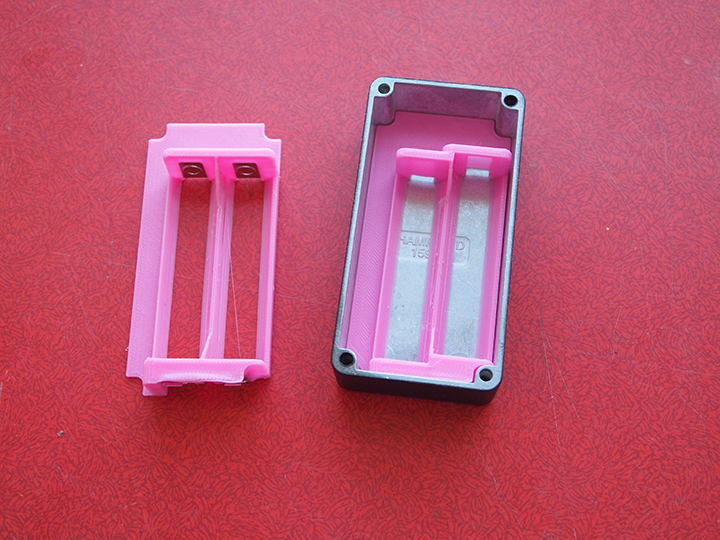

Right now working on the sled and covers for the Mrs new Mod she is thinking of putting into a short production run, girls with soldering irons are hot.

peps1

Postman

- Joined

- Dec 15, 2014

- Messages

- 779

Found this today......POM filament, as its used for driptips and insulators in RDAs, thought it would be a intringing meterial to try printing some Box mod gear with.

Polyoxymethylene (POM) filament is also known as Acetal or Polyacetal. The company DuPont uses the trade name Delrin for Acetal Resin. It is a commonly used thermoplastic to engineer specific parts. Acetal filament has high stiffness, low friction, and excellent wear resistance. It has good elastic resilience and great dimensional stability. The filament has good chemical and heat resistance. Because of it's low friction, POM is routinely used as gear wheels, ball bearings, etc. It has high impact resistance, which is one of the reasons the M16 rifle's stock is made out of POM.

The recommended print temperature is between 210°C - 225°C. Please note that Acetal degrades when overheated and may give off small amounts of formaldehyde gas. Do not keep Acetal heated above 230°C. Therefore, please always use in a well ventilated area or in a ventilation system. Please keep Acetal away from moisture and always keep filament in an airtight container with a desiccant. POM can be printed on a heated bed plate ~130°C covered in blue tape. Use hairspray on top of the blue tape for even better results. Some users prefer wood or cellulose based platforms to print on such as high density cardboard. If you have a heated chamber, then please remember to pre-heat your chamber to reduce warping.

Polyoxymethylene (POM) filament is also known as Acetal or Polyacetal. The company DuPont uses the trade name Delrin for Acetal Resin. It is a commonly used thermoplastic to engineer specific parts. Acetal filament has high stiffness, low friction, and excellent wear resistance. It has good elastic resilience and great dimensional stability. The filament has good chemical and heat resistance. Because of it's low friction, POM is routinely used as gear wheels, ball bearings, etc. It has high impact resistance, which is one of the reasons the M16 rifle's stock is made out of POM.

The recommended print temperature is between 210°C - 225°C. Please note that Acetal degrades when overheated and may give off small amounts of formaldehyde gas. Do not keep Acetal heated above 230°C. Therefore, please always use in a well ventilated area or in a ventilation system. Please keep Acetal away from moisture and always keep filament in an airtight container with a desiccant. POM can be printed on a heated bed plate ~130°C covered in blue tape. Use hairspray on top of the blue tape for even better results. Some users prefer wood or cellulose based platforms to print on such as high density cardboard. If you have a heated chamber, then please remember to pre-heat your chamber to reduce warping.

Similar threads

- Replies

- 0

- Views

- 163

- Replies

- 2

- Views

- 1K