danb

Achiever

- Joined

- Apr 13, 2014

- Messages

- 2,041

I've been considering the physical properties of different wires over the past week, running some calculations and trying to understand how we can use the data we have to guide wire choice in a TC build - ideally in a quantitative (or semi-quantitative) way. I decided to post my ideas on this subject and see what the wider community thinks. This is going to be long, but I hope it is useful/interesting to some of you. I welcome criticism, comments etc.

There are several different factors to consider when choosing a suitable wire for temperature control [TC]. While many of these factors are subjective, such as ease of use, one important factor that can be objectively measured is sensitivity. As we all know, TC works by monitoring the live resistance of the coil and converting the resistance [R] into temperature [T] based on the temperature coefficient of resistance [TCR] of the wire. TCR varies depending on the material, and is a measure of the relative increase in R associated with a 1 °C (or 1 K) change in T. It is not uncommon to see Ni200 described as the most sensitive wire because, with a TCR around 0.006 per °C, it has the highest TCR of the currently available vaping wires. However, TCR is not the whole story regarding to sensitivity - while Ni200 is the most responsive wire in terms of relative resistance change with temperature, TCR is only half the story. In fact, of the wires currently available for TC, Ni200 is without a doubt the worst wire.

What I'm calling sensitivity is the actual (as opposed to relative) resistance change of a wire as it heats up. From a practical point of view, the greater the actual change in R (ΔR) per °C, the easier it is for the device to measure, and the more accurate the T measurement is. Sensitivity in this sense is a measure of how precisely your mod can detect and control temperature. For a Ni200 coil with a resistance around 0.14 Ω, the actual change in resistance per °C is about 0.001 Ω (or 1 mΩ/°C). This is probably around the limit of reliable detection for most mods.

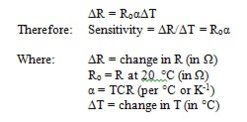

So how can we determine the sensitivity? Well, let’s look at the physical relationship between resistance temperature change:

The important thing to understand is that this equation shows sensitivity (the change in resistance per unit temperature, or ΔR/ΔT) depends equally on both TCR and the resistance of your build (Ro).

To compare the sensitivity of different wires we need to consider the combined effects of Ro and the wire’s TCR. While it is true that a 0.15 Ω Ni200 build is more sensitive than a 0.15 Ω Ti build, these correspond to totally different builds and the comparison is not very helpful. What is helpful is a comparison based on wire length - i.e. what happens if we compare sensitivity of different wires in the same build? Besides Ni200 and Ti, there are a growing number of wire options available - particularly NiFe alloys that offer a range of resistivities and TCRs to suit different builds.

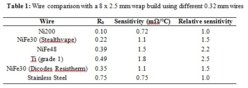

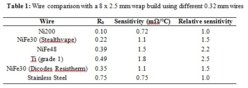

Using data from Steam Engine and examining a selection of these wires, we get the following results for 8 x 2.5 mm wraps of 0.32 mm diameter wire, with 5 mm leg length (Table 1):

(click image to enlarge table)

The relative sensitivity holds true regardless of the build - if you compare all of these wires on the same build the relative result is always that: Ni200 and SS are the least sensitive, followed by the two NiFe30 wires, followed by NiFe48, closely followed by the most sensitive, Ti. This means Ni200 or SS are the least accurate wires for TC, whereas NiFe48 and Ti are the most accurate. Another way of looking at it is that less wire (fewer wraps) is needed for a sufficiently accurate build using a more sensitive type of wire.

Ni200 and SS are accurate enough for single coil builds using thinner wire, but if you want to dual coil, use thick wire, or a combination of both, NiFe alloys or Ti are really the only sensible options. For reference, here is a table of the minimum build resistance required to achieve a benchmark “good” sensitivity of 1 mΩ/°C (in blue, Table 2). If you stick around this ballpark (or higher) then you can be confident that sensitivity will not be a problem in your TC build. I have been building about 20% lower than this with good results, and have seen positive accounts from people buliding almost 50% lower than this with Ti. Also included are values corresponding to a sensitivity of 0.5 mΩ/°C (in red, Table 2), which I think are sensible lower limits to stay above. To give a more tangible idea of what these resistances mean in terms of build limitations, the minimum number of wraps required to reach these resistances with a 2.5 mm ID single coil with two different wire thicknesses are also provided (double these numbers for dual coils).

(click image to enlarge table)

Another (but usually minor) factor to consider when choosing a wire is the effect of “static resistance”. This is the additional resistance caused by imperfect contacts in your setup. In a perfect world, the static resistance is zero, but in reality there will always be at least a small contribution. The problem with static resistance is that it does not change as the wire heats up, and thus is a source of error in your mod’s temperature measurement. The extent of disruption by static resistance depends on its magnitude relative to Ro. So a given static resistance will have the least effect on a higher resistance coil. For example, while the same build with Ni200 or SS will have similar sensitivity, the effect of any static resistance on the Ni200 build will be far more disruptive than on the SS build - so chances are the SS coil will be more accurate.

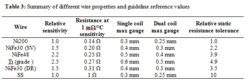

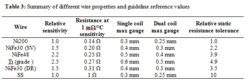

A summary (table 3) is included below with some guideline recommendations.

(click image to enlarge table)

At this point we can plainly see that Ni200 is certainly the least appropriate wire for TC. The only conceivable reason to use it is that your mod only has a Ni mode. Stealthvape NiFe30 can be used on Ni-only mods with very minimal temperature offset. I would always recommend it over Ni200. You can buy it at stealthvape.co.uk

Dicodes Resistherm NiFe30 has a similar sensitivity to Stealthvape NiFe30, but slightly better tolerance to static resistance. Resistherm is only available at 0.28 mm, and is substantially more expensive than the Stealthvape variety.

NiFe48 (= Nifethal 52 on Steam Engine) is a great option for thick wire and/or dual coils. It offers improved sensitivity compared to NiFe30. If you don't like building with Ti, this may be an option to consider. Building with this stuff is similar to building with Stealthvape NiFe30 - it's softer than kanthal, but much stronger than Ni200. You can buy it at zivipf.com (they also sell a NiFe30 similar to Stealthvape).

It seems, from what people are saying online, that NiFe wires can be dry burned (I'm not claiming to know it's safe). This may be an attractive feature for some.

Ti is currently the wire that provides the greatest TC accuracy. There are some potential issues regarding dry burning and stiffness/springyness.

SS seems to be gaining popularity, with stock SS coils for TC beginning to appear on the market. Looking at the numbers, I don't really understand why. It offers low sensitivity - comparable to Ni200 for the same build - though its high resistivity means it is the least susceptible to static resistance.

There are several different factors to consider when choosing a suitable wire for temperature control [TC]. While many of these factors are subjective, such as ease of use, one important factor that can be objectively measured is sensitivity. As we all know, TC works by monitoring the live resistance of the coil and converting the resistance [R] into temperature [T] based on the temperature coefficient of resistance [TCR] of the wire. TCR varies depending on the material, and is a measure of the relative increase in R associated with a 1 °C (or 1 K) change in T. It is not uncommon to see Ni200 described as the most sensitive wire because, with a TCR around 0.006 per °C, it has the highest TCR of the currently available vaping wires. However, TCR is not the whole story regarding to sensitivity - while Ni200 is the most responsive wire in terms of relative resistance change with temperature, TCR is only half the story. In fact, of the wires currently available for TC, Ni200 is without a doubt the worst wire.

What I'm calling sensitivity is the actual (as opposed to relative) resistance change of a wire as it heats up. From a practical point of view, the greater the actual change in R (ΔR) per °C, the easier it is for the device to measure, and the more accurate the T measurement is. Sensitivity in this sense is a measure of how precisely your mod can detect and control temperature. For a Ni200 coil with a resistance around 0.14 Ω, the actual change in resistance per °C is about 0.001 Ω (or 1 mΩ/°C). This is probably around the limit of reliable detection for most mods.

So how can we determine the sensitivity? Well, let’s look at the physical relationship between resistance temperature change:

The important thing to understand is that this equation shows sensitivity (the change in resistance per unit temperature, or ΔR/ΔT) depends equally on both TCR and the resistance of your build (Ro).

To compare the sensitivity of different wires we need to consider the combined effects of Ro and the wire’s TCR. While it is true that a 0.15 Ω Ni200 build is more sensitive than a 0.15 Ω Ti build, these correspond to totally different builds and the comparison is not very helpful. What is helpful is a comparison based on wire length - i.e. what happens if we compare sensitivity of different wires in the same build? Besides Ni200 and Ti, there are a growing number of wire options available - particularly NiFe alloys that offer a range of resistivities and TCRs to suit different builds.

Using data from Steam Engine and examining a selection of these wires, we get the following results for 8 x 2.5 mm wraps of 0.32 mm diameter wire, with 5 mm leg length (Table 1):

(click image to enlarge table)

The relative sensitivity holds true regardless of the build - if you compare all of these wires on the same build the relative result is always that: Ni200 and SS are the least sensitive, followed by the two NiFe30 wires, followed by NiFe48, closely followed by the most sensitive, Ti. This means Ni200 or SS are the least accurate wires for TC, whereas NiFe48 and Ti are the most accurate. Another way of looking at it is that less wire (fewer wraps) is needed for a sufficiently accurate build using a more sensitive type of wire.

Ni200 and SS are accurate enough for single coil builds using thinner wire, but if you want to dual coil, use thick wire, or a combination of both, NiFe alloys or Ti are really the only sensible options. For reference, here is a table of the minimum build resistance required to achieve a benchmark “good” sensitivity of 1 mΩ/°C (in blue, Table 2). If you stick around this ballpark (or higher) then you can be confident that sensitivity will not be a problem in your TC build. I have been building about 20% lower than this with good results, and have seen positive accounts from people buliding almost 50% lower than this with Ti. Also included are values corresponding to a sensitivity of 0.5 mΩ/°C (in red, Table 2), which I think are sensible lower limits to stay above. To give a more tangible idea of what these resistances mean in terms of build limitations, the minimum number of wraps required to reach these resistances with a 2.5 mm ID single coil with two different wire thicknesses are also provided (double these numbers for dual coils).

(click image to enlarge table)

Another (but usually minor) factor to consider when choosing a wire is the effect of “static resistance”. This is the additional resistance caused by imperfect contacts in your setup. In a perfect world, the static resistance is zero, but in reality there will always be at least a small contribution. The problem with static resistance is that it does not change as the wire heats up, and thus is a source of error in your mod’s temperature measurement. The extent of disruption by static resistance depends on its magnitude relative to Ro. So a given static resistance will have the least effect on a higher resistance coil. For example, while the same build with Ni200 or SS will have similar sensitivity, the effect of any static resistance on the Ni200 build will be far more disruptive than on the SS build - so chances are the SS coil will be more accurate.

A summary (table 3) is included below with some guideline recommendations.

(click image to enlarge table)

At this point we can plainly see that Ni200 is certainly the least appropriate wire for TC. The only conceivable reason to use it is that your mod only has a Ni mode. Stealthvape NiFe30 can be used on Ni-only mods with very minimal temperature offset. I would always recommend it over Ni200. You can buy it at stealthvape.co.uk

Dicodes Resistherm NiFe30 has a similar sensitivity to Stealthvape NiFe30, but slightly better tolerance to static resistance. Resistherm is only available at 0.28 mm, and is substantially more expensive than the Stealthvape variety.

NiFe48 (= Nifethal 52 on Steam Engine) is a great option for thick wire and/or dual coils. It offers improved sensitivity compared to NiFe30. If you don't like building with Ti, this may be an option to consider. Building with this stuff is similar to building with Stealthvape NiFe30 - it's softer than kanthal, but much stronger than Ni200. You can buy it at zivipf.com (they also sell a NiFe30 similar to Stealthvape).

It seems, from what people are saying online, that NiFe wires can be dry burned (I'm not claiming to know it's safe). This may be an attractive feature for some.

Ti is currently the wire that provides the greatest TC accuracy. There are some potential issues regarding dry burning and stiffness/springyness.

SS seems to be gaining popularity, with stock SS coils for TC beginning to appear on the market. Looking at the numbers, I don't really understand why. It offers low sensitivity - comparable to Ni200 for the same build - though its high resistivity means it is the least susceptible to static resistance.