Colonelboom

Vendor

- Joined

- Mar 16, 2013

- Messages

- 3,609

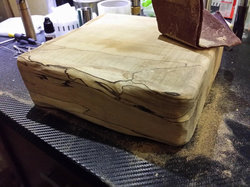

Hi modders. I have a lump of spalted ash that I intend to do very little with apart from a tiny bit of shaping (carving then sanding to suit) and then popping a few holes in for mods, atties and drip tips. I already have a 22mm forstner bit for the mod holes and will widen these a little as I finish them but offhand do you know what size the holes for drip tips are best at for a snug-ish fit? I could just go 9mm which I think is around the right size but I want to keep them held in lightly by the o-rings and figured 8.5mm would be better.

Also, any of you know off the top of your head the same dimension required for the 510 battery connectors you can buy? I want to put 5-6 in to screw my atties down for security.

cheers

Also, any of you know off the top of your head the same dimension required for the 510 battery connectors you can buy? I want to put 5-6 in to screw my atties down for security.

cheers

I will pop an order in for the 510 connectors and be patient though lol.

I will pop an order in for the 510 connectors and be patient though lol.