Darthpistachio

Postman

- Joined

- Dec 12, 2012

- Messages

- 350

I have tried all manner of ways of joining the dreaded R-NR wires together. - The standard twist method is OK but more often than not ends up a bit loose with resistance readings wavering.

The wire zappers are OK but only if you have a good quality one costing over £50 - I have a cheaper version and it works but only about 50% of the time - and then you don't want to know how many expletives have been uttered when I wind the coil onto my wick and you hear that dreaded "ping" when the join breaks! Not fun at all ...

The reef knot variation is good in principle - BUT it's bulky and awkward to get them tight together so that the connection does not suffer with resistance dancing.

No for me with experience I found that the standard twist method with a bit more of an OCD variation works the best.

You will need some good tools for this method and they are as follows:

A good quality flat nosed non toothed pliers. These are the ones sold for beading aficionados - ideal.

Plastic jawed pliers - again beading ones - ideal for holding differing diameter wires together..

Good quality snips..

last but not least the wires -of course

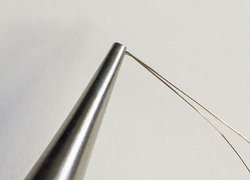

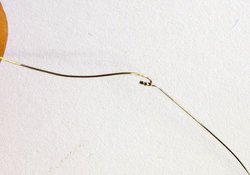

Now get the two wires alongside each other clamp them in the plastic jawed pliers and have about 8-10mm protruding and splay them apart.

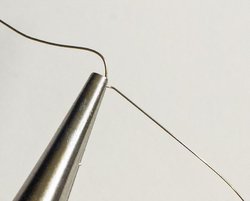

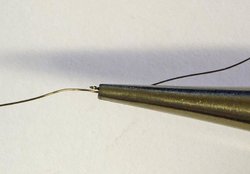

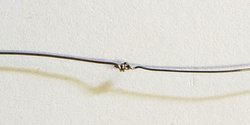

At this stage carefully twist them around each other about 4-5 times by hand...

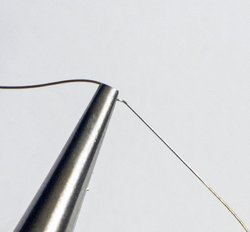

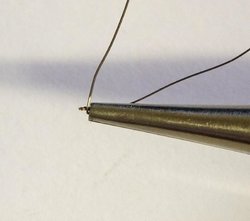

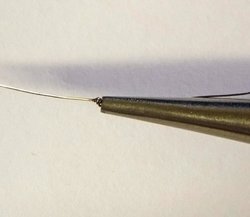

Now, using the metal pliers grip the twisted wires and continue twisting them again - this will make the twists very tight and ensure against them unraveling later on and during use - continue twists in the same direction for a further 4-5 turns ...

The wire zappers are OK but only if you have a good quality one costing over £50 - I have a cheaper version and it works but only about 50% of the time - and then you don't want to know how many expletives have been uttered when I wind the coil onto my wick and you hear that dreaded "ping" when the join breaks! Not fun at all ...

The reef knot variation is good in principle - BUT it's bulky and awkward to get them tight together so that the connection does not suffer with resistance dancing.

No for me with experience I found that the standard twist method with a bit more of an OCD variation works the best.

You will need some good tools for this method and they are as follows:

A good quality flat nosed non toothed pliers. These are the ones sold for beading aficionados - ideal.

Plastic jawed pliers - again beading ones - ideal for holding differing diameter wires together..

Good quality snips..

last but not least the wires -of course

Now get the two wires alongside each other clamp them in the plastic jawed pliers and have about 8-10mm protruding and splay them apart.

At this stage carefully twist them around each other about 4-5 times by hand...

Now, using the metal pliers grip the twisted wires and continue twisting them again - this will make the twists very tight and ensure against them unraveling later on and during use - continue twists in the same direction for a further 4-5 turns ...

Attachments

-

rnr_step1.jpg57.2 KB · Views: 83

rnr_step1.jpg57.2 KB · Views: 83 -

rnr_step2.jpg36.7 KB · Views: 87

rnr_step2.jpg36.7 KB · Views: 87 -

rnr_step3.jpg36.4 KB · Views: 93

rnr_step3.jpg36.4 KB · Views: 93 -

rnr_step4.jpg46.2 KB · Views: 84

rnr_step4.jpg46.2 KB · Views: 84 -

rnr_step5.jpg37.4 KB · Views: 90

rnr_step5.jpg37.4 KB · Views: 90 -

rnr_step6.jpg32.3 KB · Views: 83

rnr_step6.jpg32.3 KB · Views: 83 -

rnr_step8.jpg29.3 KB · Views: 85

rnr_step8.jpg29.3 KB · Views: 85 -

rnr_step9.jpg32.1 KB · Views: 86

rnr_step9.jpg32.1 KB · Views: 86 -

rnr_step10.jpg39.2 KB · Views: 84

rnr_step10.jpg39.2 KB · Views: 84 -

rnr_step11.jpg38.8 KB · Views: 32

rnr_step11.jpg38.8 KB · Views: 32

Last edited: